Biopharmaceutical

BioSMB™ is a technology that provides reduced costs and increased process efficiency in biopharmaceutical production. Flexibility is achieved through multi-column technology; its systems are designed with disposable components to be practical and functional within virtually all bioprocessing environments.

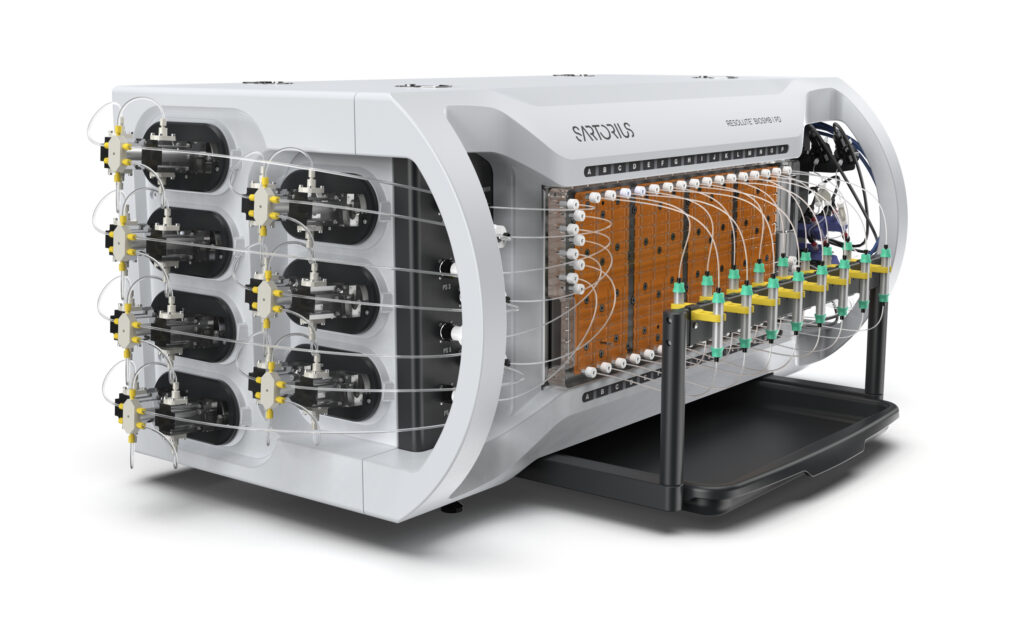

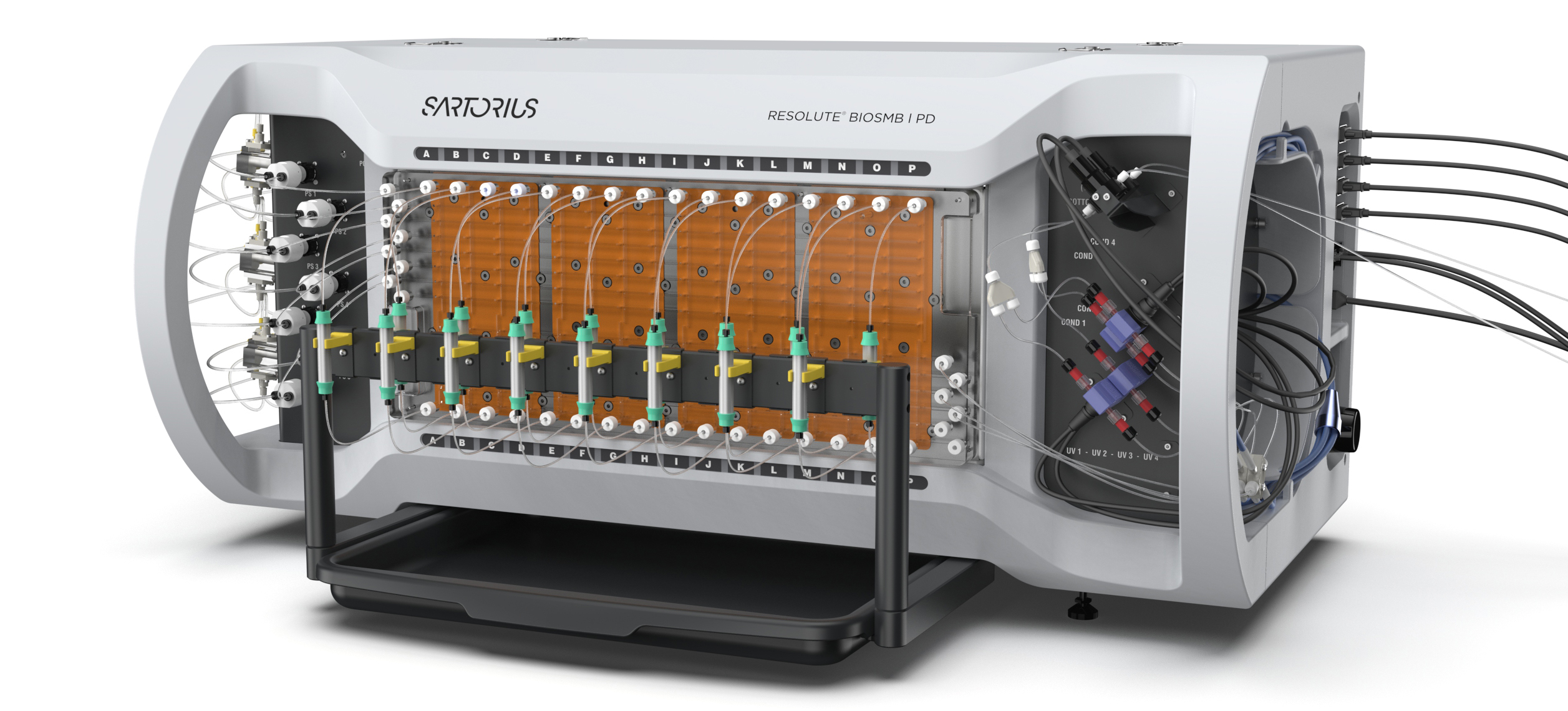

Typically the setup for production of this type is complex; the considerable amounts of tubing can be confusing and unsightly. Effective management of the fluid, tubing and pathways were key in the design. The design team utilized an intuitive left-to-right flow for the series of pathways. Two arches, one on either side of the front panel of the main unit, were designed to route the tubing within the canals, keep the area neat, and protect the fluid lines.

Fluids run through the series of columns at the front of the unit; the columns can vary in size but must be held in front of the unit to allow for proper functioning. The design team developed a rack to hold the columns; the rack was removable and fit into fold-away arms that tucked inside the unit. This made the unit more compact – a major consideration for a system of this size – and allowed for better access for setting up fluid lines.

This equipment enables biopharmaceutical-manufacturers to purify a drug product (injectable dosage form) using ‘disposables’ while consuming 1/2 the water, 1/3 of the physical space, much less (up to 80% less) of the consumable materials and less energy; this decreases the need for creating energy intensive “clean steam” to purify fixed stainless steel piping (now the industry standard) thereby providing a ‘greener’ solution.

The device was recognized with a 2011 IDA award and 2012 Good Design award for its innovative, intuitive design and positive ecological impact.