Safety Equipment

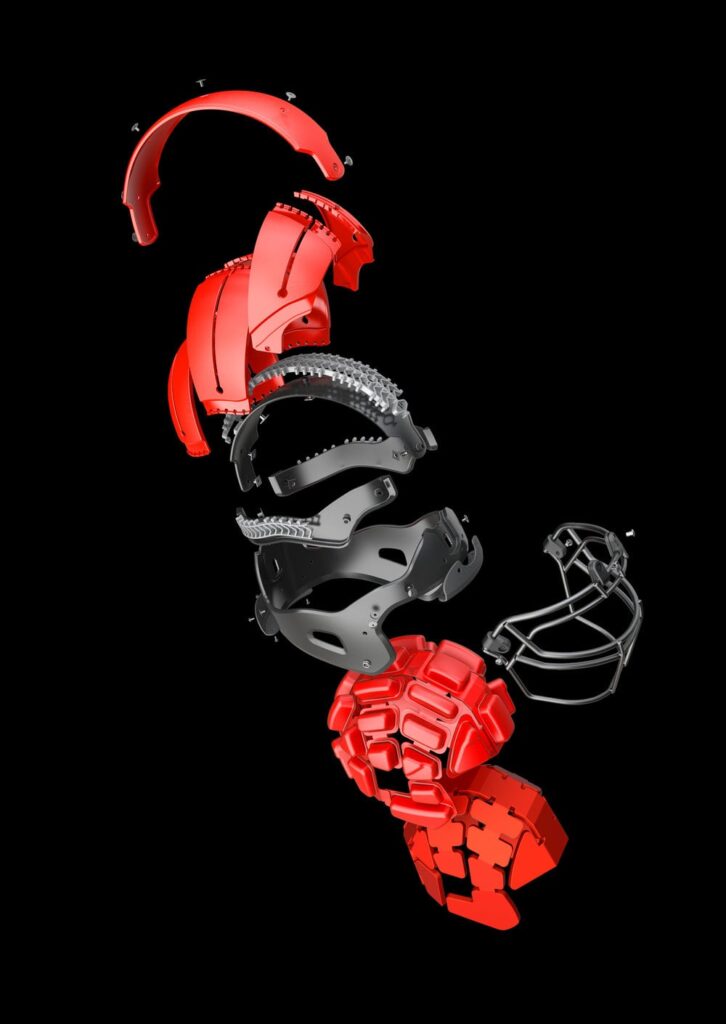

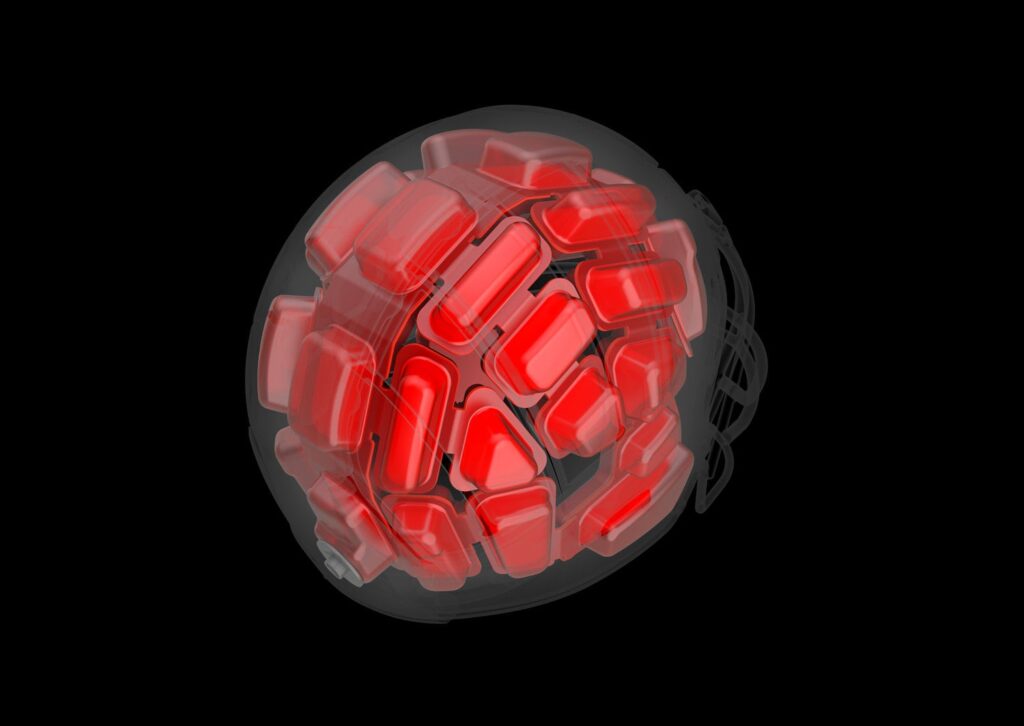

Instead of a continuous single piece, the outer shell is separated into multiple individual panels. These panels are compliantly interconnected to each other and to an underlying structural frame. Shock-absorbing polymer springs fill the spaces between the rigid panels. This allows the panels to move independently in any direction while keeping them in place.

When an individual panel moves, the Helmetek Flex Shell transmits force to the interstitial polymer material. Some of which is then passed along to adjacent panels and so on across the helmet structure, distributing impact forces around the perimeter of the head instead of concentrating them. An internal air bladder works in concert with the external panels to redistribute force. During impact, some energy is absorbed by foam inside the cell while air is forced into surrounding cells via a series of channels. Like an airbag, this action dampens without rebounding or reverberation.

A flexible, breathable protective fabric wraps the outside of the helmet providing unique decorative and branding opportunities.

The Helmetek Flex Shell is now a 2019 iF Design Award winner!