SERVICES PROVIDED

There will always be a segment of the population that enjoys the act of driving. With this in mind, many in the automotive industry envision a future where AI is used to augment and enrich, not replace, the driving experience, making it safer and more enjoyable for all.

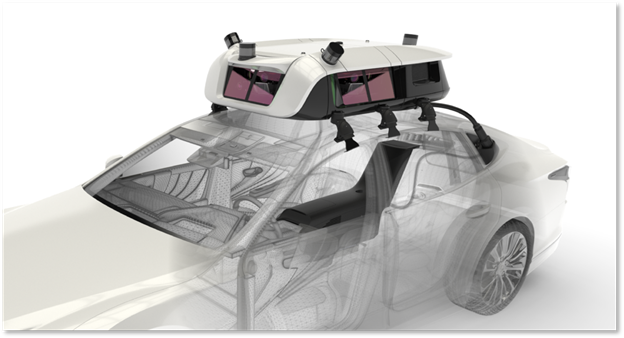

To meet the needs of their vehicle R&D programs, a major international automaker collaborated with Product Insight to develop a modular, sensor-rich roof box system called the Ground Truth Sensor Hat (GTSH) which is used by the company to provide real-time data acquisition and logging to evaluate the performance of various autonomous vehicle platforms.

The GTSH provides a single, adaptable platform for autonomous vehicle R&D, reducing cost and time of iterations while supporting greater vehicle flexibility.

The GTSH addresses key challenges posed by previous generations of the company’s autonomous test-vehicle platforms. These earlier iterations employed a highly customized approach, in which sensors and subsystem components were built into each vehicle. This drove cost and development time and made repairs and upgrades difficult.

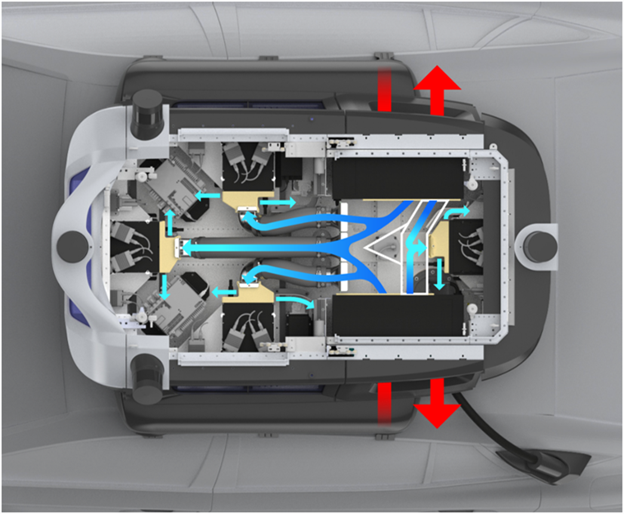

PI’s integrated design and engineering teams developed a solution that incorporates massive sensory capabilities and self-contained cooling inside a flowing, functional form, connected to data and power management modules inside the cabin via a single pass-through cable. The GTSH is purposefully designed to minimize any modifications to the vehicle. The roof box module is sized to fit on a range of vehicle sizes, and the roof clamps can be adapted to a wide variety of widths and profiles.

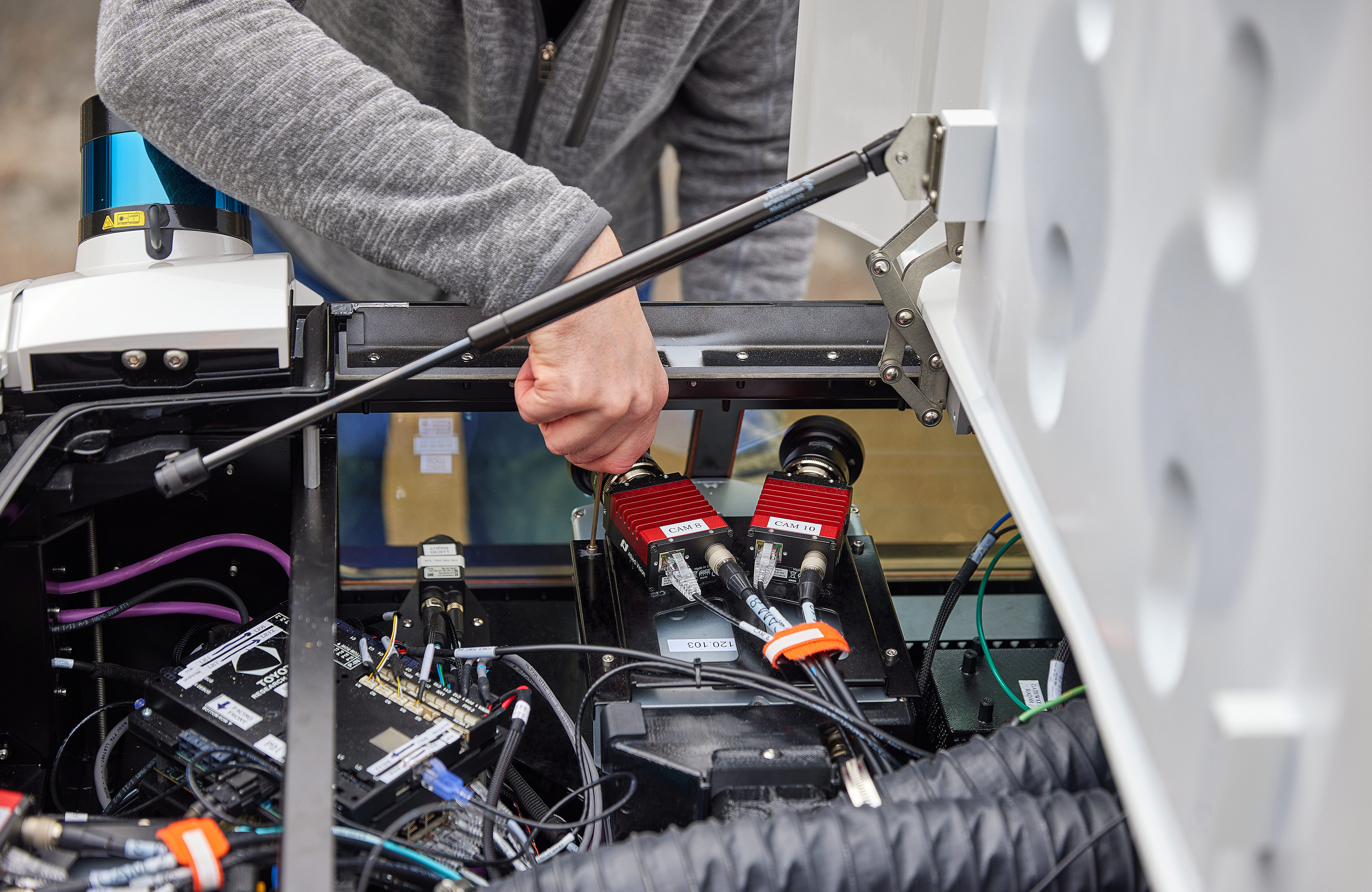

The top panels of GTSH open like a trunk hatch, providing open access to the interior of the roof box for quick service.

Inside, sensors are mounted to independent modular brackets, easing individual replacements and upgrades. The entire system can be removed when major servicing is needed.

The overall design of the GTSH is the result of a highly collaborative effort to carefully balance and optimize the internal and external elements. PI’s holistic approach was driven concurrently by the requirements of components & thermal mitigation, structure & support, service access, manufacturability, and aesthetics. This iterative process results in a design where form and function are complementary.