Where does all the waste go?

There is a dirty little secret in the medical, biotech and life science industries. While the equipment and processes used in these fields may promote human health, they also create a staggering amount of waste. A single hospital patient in the US produces, on average, roughly 34 pounds of waste each day, and this doesn’t include non-clinical research applications and other laboratory equipment that require single-use disposables, or “consumables”, to function. Adding to this problem is that much of this waste is considered biohazardous.

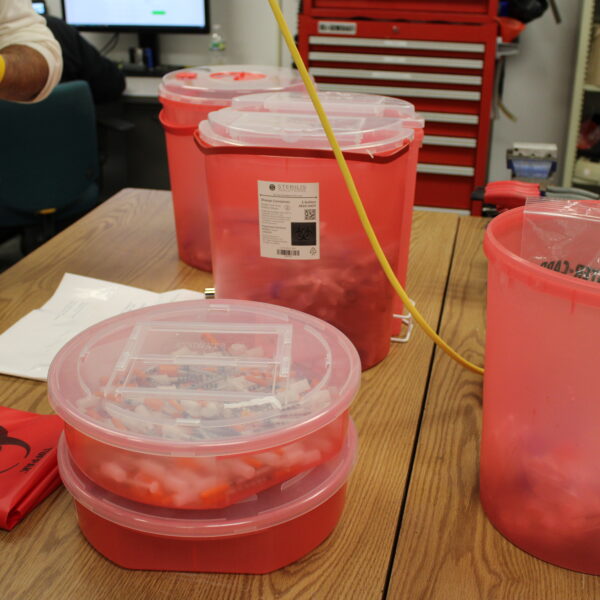

In our work with medical device and life science equipment manufacturers, minimizing the size, cost and environmental impact of the system consumables is always a priority. However, some amount of biohazardous waste is often unavoidable. Biohazard waste poses threats not only to the safety of those who directly handle it, but to much larger environments and communities––ensuring it is safely disposed of is vital. But when biohazard waste is disposed of, where does it go? What are the most effective methods of treatment and disposal? How does waste disposal intersect with environmental, financial, and accessibility considerations?

What is biohazard waste?

Biohazard waste varies slightly in definition by geographic location. Different states in the US have varying definitions and regulations, but generally, biohazard waste refers to any potentially infectious waste that could threaten the environment or public health. This waste often includes, but is not limited to, medical waste (blood, pathological waste, soiled dressings), contaminated sharps, and microbiological waste (stocks of infectious agents, laboratory cultures).

It is important to note that medical waste is one category of biohazardous waste, but not all biohazardous waste is medical waste. It is helpful to refer to specific state guidelines regarding biohazard waste, both for clarity on what constitutes biohazard waste and the recommended treatment and disposal methods for each category.

What are common disposal methods and their effectiveness?

There are no universal regulations for biohazard waste treatment and disposal. Organizations such as the International Red Cross have laid out suggestions for standardized protocols and regulations, but waste practices vary both domestically and internationally. In the US, some states such as Alabama have extensive specific treatment recommendations, while others like Illinois have more general recommendations. While this lack of standardization is certainly confusing, outlining the advantages and drawbacks of popular methods is important for both educational and industrial purposes.1

Incineration

Incineration is the most widely practiced method of biohazardous waste disposal. Along with autoclaving, incineration is a recommended waste treatment for every state. In this method, waste is burned at such high temperatures, all contaminants are destroyed, and the waste becomes particles of ash or gas. Incineration is a simple and popular method as it requires no pre-processing such as shredding. Incineration can be used for treating virtually any kind of waste, except for those with heavy or high metal content.

While incineration will most likely remain a popular disposal method due to its effectiveness and speed in dealing with large amounts of waste, it is vital to ensure that incinerators themselves comply with international regulations for emissions by operating at 850-1150°C and are fitted with specific gas-cleaning instruments.2 While incineration is fast and extremely effective at decontaminating and destroying large quantities of waste, it raises significant environmental concerns. Incineration can release substantial pollutants, specifically when incinerators are not properly operated or are used for waste that contains harmful chemicals. Additionally, incinerators that comply well with emission regulations require high operating costs, both in machinery and labor. In many states, incineration is the required method for disposing specific types of waste, such as contaminated pathological waste.3

Autoclaving

Autoclaving is another widely practiced method of biohazardous waste disposal. It refers to the process of sterilizing waste in a highly pressurized, steam-heated chamber. Once waste is fully autoclaved, it is often shredded and then disposed of in a landfill along with other normal trash. Some autoclaved items such as contaminated plastic or glass containers can be reused as is or melted down to create new items.4 Most waste can be treated through autoclaving, including soiled bandages, biological cultures and stocks, sharps, and other surgical equipment. Pathological waste and waste containing corrosives, carcinogens, or other radioactive elements should not be autoclaved.5

While autoclaving is extremely effective, has relatively low operating costs, and releases minimal harmful emissions when performed correctly, the machinery requires substantial installation costs and electricity. Despite its advantages, the environmental impact of autoclaving cannot be missed; it requires immense amounts of energy to power autoclaves, as steam technology requires significant energy and water to run for extended periods of time.6

The process is a much more time-consuming method, generally taking about seventy minutes to complete, while incineration is essentially instantaneous. Additionally, the shape, size, and weight of waste does not change during autoclaving, and the subsequent shredding that is required prevents further use for non-recyclable waste items. To mitigate this environmental impact, it is important to turn on and use autoclaves only when they are full, instead of running them continuously and wasting resources.

Microwaving

Several studies suggest that microwaving is one of, if not the most, environmentally friendly waste disposal methods that retains an extremely high level of disinfection. Microwaving works by transmitting energy in the form of microwaves at a frequency of about 2450Hz to the waste, which internally heats and disinfects it. Since microwave radiation only works on water as opposed to solid components of waste, waste must be wet or damp before being microwaved. If waste is not naturally wet, water is added to the waste, or an additional humidifier is supplied. Before microwaving, waste undergoes shredding to improve the efficacy of microwaving and decrease waste volume by up to eighty percent.7

Microwaving can be used to treat many kinds of biohazardous waste, including contaminated gauze or bandages, lab cultures and stocks, sharps, non-chemical laboratory wastes, and surgical or other hospital materials that have been in contact with blood or other bodily fluids. Microwaving is generally not recommended for pathological waste and should not be used for hazardous chemical or radiological waste.8 Although sophisticated microwaving machinery is relatively expensive to purchase and install, microwaving is an attractive alternative to incineration and autoclaving for its comparatively lower operational costs, as well as less recurring maintenance, energy usage, and time. Microwaving waste is significantly less financially and environmentally draining over time than autoclaving, costing about seventy-five percent less annually and drastically reducing carbon footprint.9

Chemical Disinfection

Chemical disinfection is a less common method of waste treatment. A chemical such as bleach, ammonium salts, or lime is often mixed with the waste to disinfect it. Chemical disinfection is mainly appropriate for treating liquid waste such as blood or other pathological secretions, and hospital sewage.10 Although chemical disinfection is a relatively cheap, accessible, and straight-forward method of waste treatment, its drawbacks and limited usage cases decrease its popularity. While the chemicals themselves are dangerous and can release toxic fumes when mixed with certain wastes, the treated waste must be disposed of with regular non-hazardous sewage. The waste is not reduced in size or volume, which contributes to overburdened sewage systems and general waste disposal backlog.11

Burial Pit / Landfill Disposal

Disposing untreated waste in a burial pit or landfill is not a recommended method. Its risks and disadvantages greatly outweigh its advantages, the latter mainly being simplicity and relatively low costs. Since the waste remains untreated, it poses risks of water and land pollution, odor, and harming the health of animals and nearby people. Landfills for untreated waste also require sizable amounts of uninhabited land, fencing, and security to prevent scavengers accessing waste and other breeches of safety. Ultimately, most treated waste ends up in a landfill of some kind––but dumping untreated waste is a recipe for both public health and environmental harm.12

How does waste end up there in the first place?

Just as regulations vary by location, so too do the most appropriate practices––what works for a well-funded large research hospital in Massachusetts may not work for a small rural hospital in West Virginia. Poorly funded hospitals often lack access to higher-tech treatment methods, which increases unsafe disposal practices such as dumping and general mismanagement. The cost of transporting medical waste also presents a sizeable problem.13 Determining the accessibility of on-site versus off-site disposal is another factor that may limit access to more eco-friendly methods such as microwaving or autoclaving.

However, what ends up in a red bin is ultimately an individual’s decision, which introduces the potential for errors. Medical practitioners tend to be cautious when it comes to waste disposal, resulting in a significant portion of non-biohazardous waste unnecessarily funneled through the expensive and polluting processes described above. While it’s common for facilities in lower-income areas to lack adequate education and support regarding proper waste disposal, this issue extends across all socioeconomic lines.

What role can design play?

Although education and training at the facility level are important for minimizing biohazardous waste streams, device design has a huge role to play. In our next installment of this series, we will explore the ways that product design can help to address the environmental and economic impacts of biohazardous waste. Be sure to keep up with our Journal for the next installment and more subjects that design plays a role in.

Notes

1 Medical Waste Management (Geneva: International Committee of the Red Cross, 2011), https://shop.icrc.org/medical-waste-management-pdf-en.html.

2 “Biohazard Waste Disposal,” MedPro Disposal, https://www.medprodisposal.com/biohazard-waste-disposal/.

3 Medical Waste Management, International Committee of the Red Cross.

4 “Biohazard Waste Disposal,” MedPro Disposal.

5 “Autoclaving Guidelines for Biohazardous Waste,” University of Virginia, last modified April 3, 2012, https://ehs.virginia.edu/biosafety/bio.documents/Autoclaving_Guidelines.pdf.

6Emily Greenfield, “The Impact of Autoclave on Environment,” Sigma Earth, last modified July 26, 2022,https://sigmaearth.com/impact-of-autoclave/.

7 “Microwave Treatment,” Malsparo, https://www.malsparo.com/treat2.htm#:~:text=While%20an%20autoclave%20provides%20heat,is%20water%20in%20the%20waste.

8 Andleep Zahra, “Microwave Technology: An Emerging Tool for Biohazard Waste Treatment,” My Waste Solution, last modified July 16, 2021, https://blog.mywastesolution.com/microwave-technology-an-emerging-tool-for-biohazard-waste-treatment/.

9 Klaus Zimmerman, “Microwave as an emerging technology for the treatment of biohazardous waste: mini-review,” Waste Management and Research 35, issue 5 (2017). https://journals.sagepub.com/doi/full/10.1177/0734242X16684385.

10-12 Medical Waste Management, International Committee of the Red Cross.

13 Zimmerman, “Microwave as an emerging technology.”