In Part 1 of this series, we took a deep dive into what happens to regulated medical waste, aka biohazardous waste, to shed some light on the size and scope of this complicated issue. In this installment, we will focus on one of the major components of this waste stream, single-use disposables, and explore where they come from, why reducing them is important, and what design strategies can help to reduce their impact in the first place.

The Single-Use Default

Visit any hospital room or laboratory and it’s quickly apparent how ubiquitous single-use materials are in the healthcare and life science industries. Some items such as pipette tips, vials, well plates, IV bags, tube sets, sharps, and others are high-volume commodities, mostly plastic, used by the billions each year. In addition, most medical devices and life science instruments require specialty “consumables” to function, such as custom cartridges, reagents, or fluidics.

While these unique consumables help to ensure consistency and quality of outcome in a convenient, easy to deploy package, they are also an important source of revenue for device manufacturers. This so-called “razor and blade” business model hasn’t always incentivized (or rewarded) efficient material use, but market forces are now rapidly changing that dynamic.

Why Should Device Makers Care?

Preparing a new product for market adoption and success involves understanding and considering the needs of all users. Products in this space may have several “users” whose interactions with the device must be carefully thought through, including patients, lab techs, physicians, nurses, and even service engineers. But one user is sometimes overlooked: the customer.

Hospitals, universities, and labs purchase equipment, pay for the consumables to keep them running and then foot the bill for all the trash they produce. Regulated medical waste disposal costs up to 10 times as much as standard waste1, so cost pressures are not trivial. Additionally, these institutions are under increasing regulatory and societal pressures to reach net zero emission targets. Device makers that don’t take these issues seriously, and design their systems accordingly, risk hurting market adoption and open themselves up to competition.

How Can Design Make a Difference?

Although every situation is unique, there are some best-practice strategies that device manufacturers and their development teams should keep in mind to help reduce waste stream impacts.

Look at Re-Use where Risk is Low

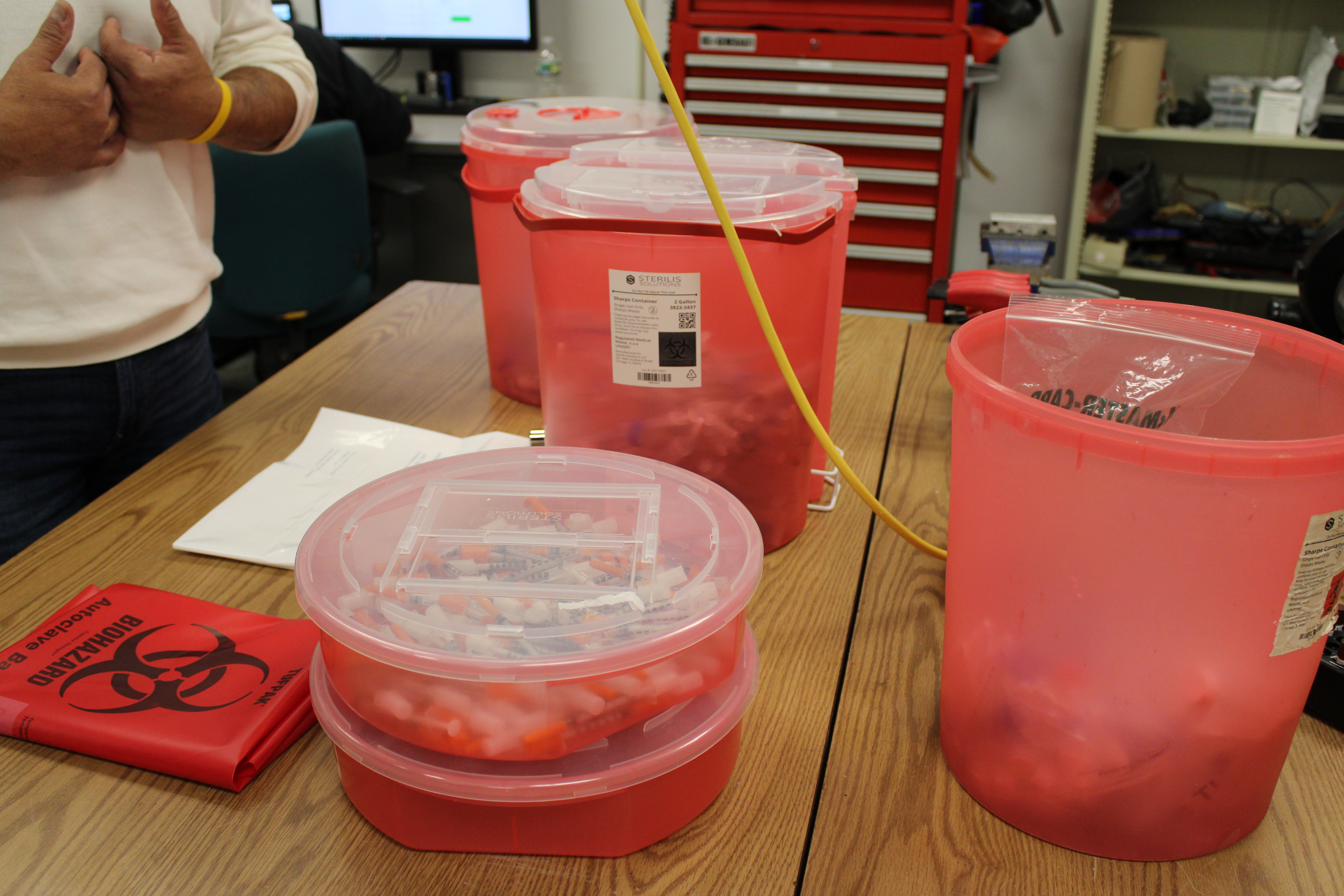

Incorporate reusable elements, such as refillable containers, or disposables that can be used more than once. Resist thinking of disposability as the default. Although truly hazardous materials should be “red-bagged”, a surprising amount of non-regulated waste ends up there (more on that below) because operators would rather be overly cautious than make a mistake. Parts that can be easily cleaned or pose no contamination risk are good candidates for re-use.

Minimize Structure

Design any load-bearing structure into the equipment, not the consumable. Requiring a disposable item to resist significant force, or hold high levels of accuracy, increases the cost of manufacturing and disposal. Instead, let the equipment do the heavy lifting.

Make Sorting Simpler

A recent study conducted at Massachusetts General Hospital found that 85% of items in biohazard red bags did not meet the requirements of regulated medical waste.1 This means that facilities like MGH are paying more than 4 times what they should for disposal fees. Purposefully designing equipment to keep biohazardous components isolated and easy to sort from normal waste stream disposables will go a long way to reducing costs and impact without placing additional burden on users.

Don’t Mix Materials

There are already in place robust recycling programs for some of the plastics commonly used in healthcare, like polypropylene (PP). As in all recycling, a single material stream, free of contamination, is best. But this doesn’t mean that biohazardous disposables can’t be recycled. It’s all about material choices.

Many facilities are opting to treat their medical waste on-site with smaller batch sterilizers, such as the Remediator from Sterilis Solutions, that provide greater control and traceability compared to third-party haulers. Crucially, these systems also enable facilities to collect and batch-process medical waste by material type. For example, if a Remediator was loaded with hazardous disposables made entirely of PP what comes out is 100% recyclable plastic flakes. And as the need for waste reduction and carbon accounting continues to grow, equipment designed to work with on-site batch sterilization will have a competitive advantage.

Start with the Ending

Delivering today’s cutting-edge science involves meeting a daunting array of technical and regulatory challenges, so waste reduction hasn’t typically been the highest priority for new product developers. But with cost concerns and sustainability initiatives on the rise, customers are looking to equipment manufacturers to provide better solutions to help them meet their goals, making waste reduction increasingly a driver of market adoption.

Waste reduction strategies like those described here are most successful when they are part of the earliest planning stages of a new product. In this sense, you should start every project by considering how it ends. With a little “preventative medicine”, we can make healthcare’s dirty little secret a thing of the past.

Learn along with us as we talk to experts through our blog posts and Webinars on our Journal.

Notes

1 Alger, S. (2020, September 24). Waste generation by hospital emergency departments is highlighted for first time in a mass general study. Massachusetts General Hospital. https://www.massgeneral.org/news/press-release/waste-generation-by-hospital-emergency-departments-is-highlighted-for-first-time-in-a-mass-general-study