Applying sustainability in design to biotech, medical and commercial equipment is the right thing to do and it’s good for business, too. Here’s a few ways to get started.

Sustainability is reaching a tipping point in the collective consciousness, with the announcement of new circular business initiatives, policies and products seemingly by the week. But when you think of sustainably designed products, what comes to mind?

Perhaps it’s a pair of sneakers made using reclaimed ocean plastics or factory scraps. Maybe it’s the circular packaging service that lets you endlessly refill without creating trash. Even electric cars are finding their way into virtually every manufacturer’s lineup. No doubt, it’s easier than ever to go green when you go shopping.

And while these are great examples, they are all “consumer goods” – sold through retail markets for end users like you and me. But what about non-consumer products such as biotech instruments, laboratory equipment, medical devices and commercial equipment? There may be fewer high-profile examples of sustainability in these industries, but is that because it can’t be done? Can sustainable design practically provide real value in these sectors?

While it may seem that sustainable design is better suited to consumer goods, applying it to equipment is just as important for the environment, can have significant positive impact for your business, and is easier than you think.

Here are just a few of the sustainable design strategies that can be adopted, starting today, to make a real difference.

Consumables:

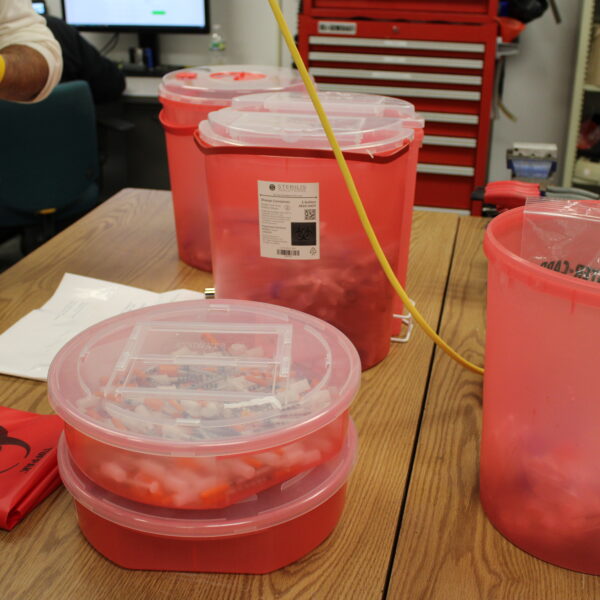

Most instruments, especially in the life sciences, require sample carriers, pipette tips, and other consumables to run their processes. These create a shocking amount of waste and represent a major source of emissions for many instruments.

Applying sustainability principals and reducing consumables volume can be a triple win: for the manufacturer, the customer and the environment. Lower volume consumables are less expensive to produce and ship, less expensive to dispose of, and reduce downstream emissions. In a recent project for a biotech equipment client we reduced the carbon footprint of their main consumable by 67% through modest design changes and reduced manufacturing costs, all without affecting performance.

Energy Use:

Because of the long useful life of scientific equipment, even modest reductions in energy use have a significant environmental impact while reducing cost of ownership for the end customer. Sourcing high-efficiency components, employing heat recapture or passive cooling techniques, and implementing automatic low-power modes are all well-known strategies for reducing energy consumption, and systems-level approaches such as process optimization can yield additional savings. These can be applied with known approaches to existing products. When efficiency goes up, cost of ownership goes down, which is good news for your customer’s bottom line as well.

Repair and Modularity:

Complex instruments, even reliable ones, will need a few repairs now and then. Designing for easy repair will keep downtime to a minimum and help prolong the useful life of the instrument, delaying its entry into the landfill.

Along with easy repairs, designing for modularity with swappable component upgrades also helps keep devices relevant and in-service for longer. Consider user-interface hardware: displays go obsolete quickly and accepted standards for I/O constantly evolve. Building in the potential for future upgrades gives customers a reason to stick with your brand, give you a lucrative, new revenue stream, and keeps the rest of the instrument out of the waste stream.

Materials:

Physical materials embody all the energy used, and carbon released, in their production, so it’s beneficial to apply materials as sparingly and carefully as possible.

Since equipment is often large and dense with electronics, material reduction and mitigation strategies can be very effective at reducing environmental impact. Such strategies include light-weighting, sourcing biogenic or recycled content, designing for disassembly and end-of-life resource recovery. A leaner, lighter instrument can also be less expensive to build, cheaper to ship, and easier to install.

Sustainability in design is good design, regardless the industry. And the particular characteristics of most equipment – large size, long life, high complexity, energy use and consumables – present myriad opportunities to make meaningful improvements for the environment, your customers and your business. And you can reap the benefits without rocket science, just by applying known design techniques and well-understood solutions.

So the real question is: what are you waiting for?